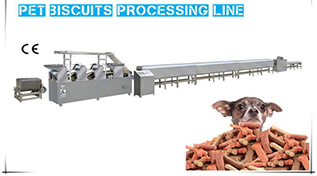

An Overview of Pet Snack Production Line

Pets are like family to many people, and pet owners are always looking for ways to treat their furry friends with nutritious and delicious snacks. With the increasing demand for pet snacks, the production of these treats has become a thriving industry. The pet snack production line is a crucial component of this industry, as it determines the quality, efficiency, and output of the production process.

Production Process

The pet snack production line typically consists of several stages, each designed to produce different types of pet snacks. The stages include mixing, shaping, baking, cooling, packaging, and storage.

1. The production of pet snacks start with the mixing of ingredients, which typically include carbohydrates, proteins, and fats. This mixture is then shaped into various forms, such as bars, bites, or bites.

2. The next stage is baking, which is an essential step in the production process. The shaped mixture is baked in ovens, where it is exposed to high heat and pressure. This process helps to cook the mixture evenly, ensuring that the pet snacks have the right texture and taste. After baking, the snacks are then cooled to room temperature, to prevent spoilage and ensure their longevity.

3. Packaging is the next stage in the pet snack production line. The snacks are packaged in airtight containers, which help to maintain their freshness and quality. The packaging materials used must be safe for pets and should not contain any harmful chemicals or toxins.

4. The final stage in the pet snack production line is storage. The packaged snacks are stored in a cool and dry place, to prevent spoilage and ensure their longevity. The storage facilities must be equipped with proper temperature control systems, to maintain the quality and freshness of the pet snacks.

Quality control is an essential component of the pet snack production line. The production process must be monitored and controlled to ensure that the pet snacks are of high quality, nutritious, and safe for pets to consume. This is achieved through regular testing and monitoring of the ingredients, production processes, and final products.

Benefits

The pet snack production line provides several benefits to pet owners and food extrusion equipment manufacturers. Some of these benefits include:

High Efficiency: The production line is designed to produce high volumes of pet snacks, ensuring that the demand for these treats is met. This helps manufacturers to increase their output and profits, while also ensuring that pet owners have access to a constant supply of nutritious and delicious snacks for their pets.

Consistency: The production line ensures that the pet snacks are produced consistently, with the same quality, texture, and taste. This consistency helps to build trust in the brand and ensures that pet owners can rely on the snacks to be safe and nutritious for their pets.

Cost-effectiveness: The pet snack production line is cost-effective, as it reduces the need for manual labor and improves the efficiency of the production process. This helps manufacturers to save money on labor costs, while also ensuring that the pet snacks are produced at a lower cost.

Increased Productivity: The production line helps to increase productivity, as it reduces the need for manual labor and improves the efficiency of the production process. This helps manufacturers to increase their output and profits, while also ensuring that pet owners have access to a constant supply of nutritious and delicious snacks for their pets.

评论

发表评论